How to Design a Power Delivery System

Imagine for a second that you had a project car that you were adding any of the following to:

- Electric Cooling Fans

- Electric Fuel Pump

- High Performance Ignition System

- Audio System

- Aftermarket Air Conditioning System

- Electronic Fuel Injection

- Etc.

Then let’s say you’ve ordered all of these things and did the thing car guys are most hesitant to do – read the installation instructions. Within each manual, you find the same thing said over and over again – You must connect the power and ground leads directly to the battery! OK, how do you pull that off without looking like Swap Meet Louie when you pop the hood? Well, you’ve come to the right place.

Connecting Directly to the Battery

So, why does every manual you’ve opened direct you to do that? Simple. Because the battery is the single best filter in the charging system. Alternators create ripple (residual AC Voltage) as a function of rectifying the AC Voltage they generate to DC Voltage. Accessories create noise – pops, ticks, back EMF, etc. as a function of them performing work. So why then do all of the manufacturers instruct you to connect all of these things directly to the battery? Because 1) Each manufacturer assumes theirs is the only accessory that matters and 2) Most aftermarket manufacturers simply do not have the resources it takes to engineer and implement the kind of filtering for their products that the OEMs can.

So, go out to your 2024 vehicle and locate the battery. Notice a gaggle of leads tied directly to the battery? Nope. What you will typically see nearby is a Fuse / Relay Center or PDM (Power Distribution Module) as many car manufacturers refer to them. There are many reasons – serviceability and utility are the main two. Typically, the PDM is fed via a single cable which is integrated into the positive battery cable assy.

Serviceability

Imagine AAA trying to swap a dead battery in the Waffle Hose parking lot at 2 AM (hey, we’ve all been there) and you’ve got 38 power leads sprouting from the battery in all different directions which prevent the battery from coming out. First tool that guy is reaching for is a diagonal cutters. Imagine trying to diagnose a vehicle that just quit running while you were rolling down I-8. Now, which one of these fuse holders went to the fuel pump? It’s just so easy to avoid all this to begin with!

Here are some examples of let’s just get it done vs let’s get it done correctly. Which would you prefer in your prized possession?

Sure, it takes a bit longer to do the work correctly but the end results speak for themselves!

Utility

Pull out the owners manual for any modern vehicle you own, go to the index, and look up Fuses. There you’ll find a complete layout of the fuse panel (or Fuse / Relay center) showing you what fuse feeds what, what its rating is, and oh yeah – there are even spare fuses available to you. In short order, you can get right to the problem. In addition, most modern vehicles have a legend embossed directly into the underside of the fuse center. You can do the very same thing (see the Fully Assembled Close-up photo below).

The Correct Approach

Understanding what to connect to the battery itself requires a bit of an understanding of what the function of the battery is when the vehicle is running and not running. That’s beyond the scope of this article, but outlined fully in our Charging Systems 101 article. But let’s say that we knew that, which we do . . . so we’re a bit selective about which accessories we always tie directly to the battery terminals. Here’s the list:

- Power / Ground leads from any aftermarket EFI System

- Power Lead(s) to supply auxiliary Power Distribution Blocks and / or Power Distribution Centers (PDCs)

The alternator isn’t considered an accessory. However, we may also tie the charge lead from the alternator to the battery positive terminal. It just depends on the particular interface and I’ve expanded on that below.

A bit shorter than you imagined, huh? Any wires or cables which you do connect to the battery terminals directly should be routed in such a way that they follow the main cables at least 6-12″ along their run. The net result is clean, neat, and serviceable. Need to swap the battery at 3AM on the side of the road? No problem.

Our Custom Cable Builders allow you to build and order battery cables to your exact specifications – using traditional or aftermarket battery terminals, with many variations to choose from in both top and side post!

So, what about all the rest of the stuff you’ve got??

Our Formula

As you learned in the Charging Systems 101 article, the battery is merely a load which requires current from the alternator to keep a surface a charge on it with the engine running in any correctly designed charging system. Of course, it’s also a great filter as I mentioned earlier – so we do leverage that. I prefer not to use the battery terminals for power distribution for a host of aftermarket accessories – which is what you’re really doing when you tie all your power leads to them. We have far better parts available to us today than ever, so let’s make use of them.

Large Cable Power Distribution

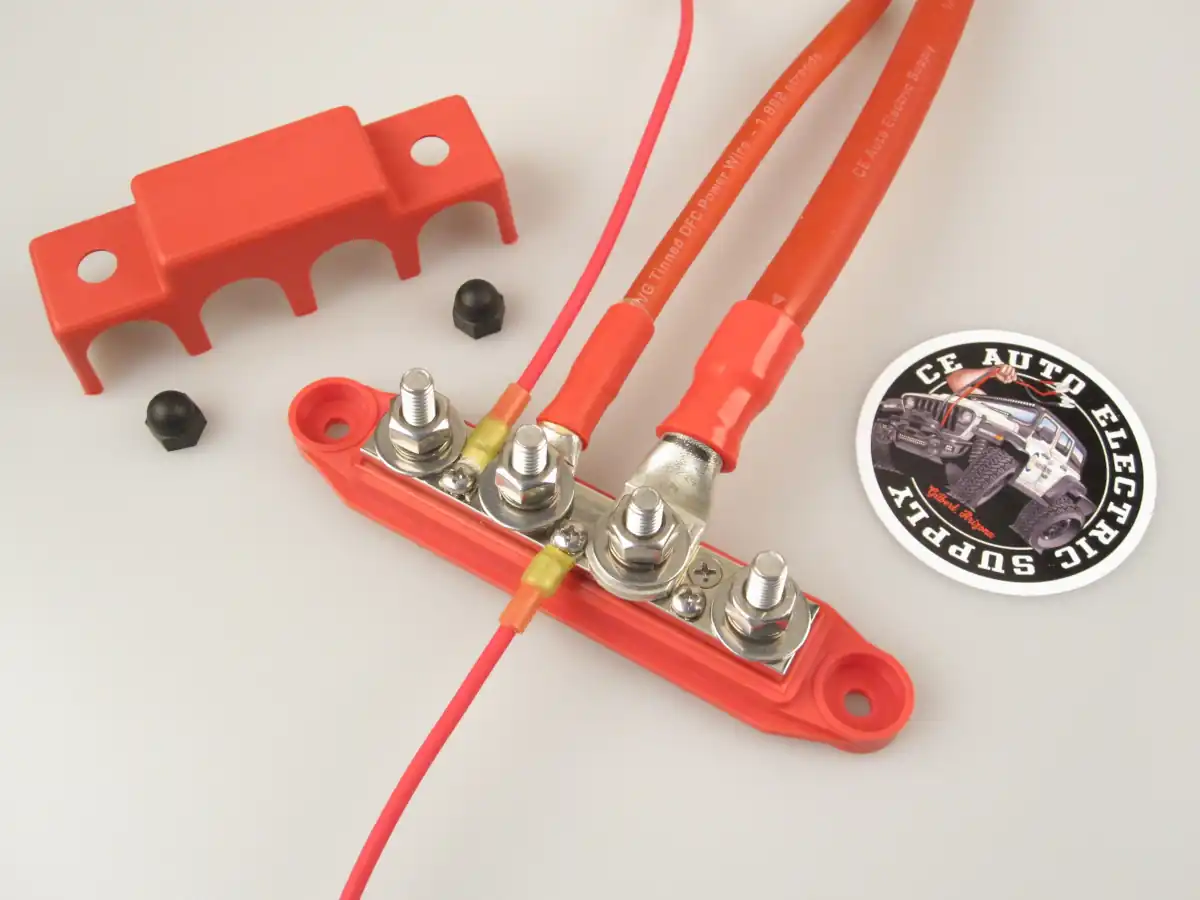

We have two kinds of Power Distribution Products – fused and non-fused. Fused Power Distribution Blocks are ideal when you’ve got a bunch of self-contained accessories which simply require a fused connection to the battery. Non-fused Power Distribution Blocks are ideal when you’ve got a need to connect numerous large cables to a junction point. And some products lend themselves well to both applications.

Power Distribution Centers (PDCs)

Our Waterproof PDCs are ideal to house fuses and relays which are used to perform specific tasks to control things like fuel pumps, water pumps, electric fans, headlights, etc. It’s also easy to add all kinds of functionality in these – built-in Hot Start Relay Kit, switched fuse outputs to power low current accessories, etc. This has the very same utility of the fuse / relay center you’ll find in modern vehicles – under the hood and elsewhere. And, we’ve given you all the tools necessary to build it yourself or to have us build it for you to your specifications.

Building such a power center for your vehicle is quite rewarding and the net result is . . . well, just what the doctor ordered. Here’s an example of the power center our Production Manager Chris Nelson build for his 2007 Chevrolet Duramax 2500 Classic. This allowed him to add all of the LED lighting he wanted. The spare fuse holder will be used to supply power to his yet to be built audio system.

Tying it All Together

So, here’s our formula in a nutshell. I’ve provided diagrams for both front-mounted and rear-mounted batteries as they are different. If you’re running a rear-mounted battery but not using a disconnect switch, or you’re using a different kind of disconnect switch, don’t worry – the stuff up front and in the rear is identical!

Grounding

So, where is the ground bus here? All my accessories have ground leads too . . . In vehicles, we don’t home run our grounds like we do in residential and commercial. We have a formula for that as well and it’s outlined fully in our Getting Grounded article.

Execution

Between the Books, Articles, and our product offering, we’ve gone out of our way to provide the information you need to complete projects of any scale. Now it’s time to dig in and get your hands dirty. This is where planning* saves you time, frustration, and money.

*Want to understand more about planning as it pertains to large projects? Then pick up a copy of my book Automotive Wiring and Electrical Systems Vol 2: Projects. This will save you countless hours! You’ll thank me later.