The Olds’ – My 1971 Pro Street Oldsmobile Cutlass (OLDZCUL)

I grew up watching car movies. Ya’ know the kind – American Graffiti, Vanishing Point, Bullitt, The Wraith (definitely at the drive-in), etc. But two movies really stick out – My Science Project and The Road Warrior. The opening scene of The Road Warrior is burned into my psyche. [It would be at least a decade later before I saw the original Mad Max to learn how the Intercepter originated.] Then there’s Vince in My Science Project –Hit the blower! This was the stuff of dreams for a kid. The Hollywood Knights only helped to solidify my position – one day I’d own a car with a blower.

The Hunt Begins!

In 2006, I began looking for a Pro Street project vehicle which I could purchase reasonably and finish it to my liking. I came across the Olds’ on eBay. In a sea of similar and common, it just jumped out at me. Now keep in mind, I’m not an Olds’ guy or any kind of car brand guy – that’s just not me. But here was this Olds’ . . . the lines, the color, the way the tires fit in the quarter. Here was my project. Without permission of the wife (long an ex-wife), I bid on the vehicle and won it. Only one problem, it was in Ohio. So, I flew into Ohio, payed the gentleman for it, and arranged transport. According to him, he purchased the car from a guy that purchased it from the original builder. The story went that it was originally owned by a service advisor at a local dealership. He built it to be a race car and it had a 427ci BBC which was bored and stroked. After a season of racing, it sat. When they tried to start the engine next race season, they dumped fuel in the carbs and hydrauliced a rod, damaging the block in the process. So, the owner sold it rather than repair it, it changed hands a few times, and here we were. As it sat, it had a running 396ci BBC in it with a Weiand 6-71 blower, a “nitrous” cam, and two Edelbrock 1405 600cfm carbs. He was kind enough to allow me to keep it in his garage until the truck showed. The next 30 days seemed like forever . . .

The Olds’ Arrives

When it showed up, and I dug into it to make a list of what was necessary to get it road worthy, that list was extensive. The fuel system – a hazard. Brakes – a hazard. Harnesses / seats – a hazard. The engine started and ran but it didn’t run well and it got hot quickly. The cooling system was an afterthought with two dinky fans that wouldn’t have kept a lawn mower engine cool, let alone a blown big block in Phoenix. And of course the electrical system – yep, an absolute hazard. All forgiven at this point as I was absolutely mesmerized by it . . . the sound of the blower, the paint, the lines, imagining cruising it . . . so it was difficult to be objective!

I spent the next few months working on it every chance I got and it was really enjoyable. I took it in stages, tackling one trouble area at a time. After dropping in the crown jewel – a brand new Ron Davis radiator, I was to the point where I needed help with the engine. Unfortunately, nobody in my network knew anything about blower motors – as if they somehow defied the laws of physics. So, I was determined to become an expert. But for now, I needed help to get it running correctly. After lots of asking, a friend referred me to this guy in Scottsdale that had been racing fuel cars since the 1960s – Ron Fassl. Ron was game and I arranged to get the car to him (via a flat bed).

Ron Fassl to the Rescue

When I pulled it into the parking lot, he walked out, stood next to it, listened to it, and had me shut if off. I arranged to leave the car with him for an analysis and they got right down to it. They immediately determined that it had carbon monoxide in the coolant. In a few days, I was up there to get the full analysis. To my surprise, the engine was out of the car and in pieces. Buddy, this thing is a disaster. The heads weren’t tight, cylinders 1 & 5 had coolant in them, the camshaft is all wrong for this motor, the crank journals are full of pitting and scores, the gears in the blower are shagged out, the rotors in the blower are pitted from running methanol through it . . . and it’s a 396! I don’t like 396s . . .

My heart just sank.

Buddy, let’s find you a nice engine for it and we’ll have you in business. I’ve got a line on a 400 small block, we can make some power with that! But . . . I was hoping to run a big block. OK, we can do that too. He takes me over to a corner in the shop, shows me a pile of stuff under a tarp, pulls the tarp off, and here is this fully disassembled big block chevy with freshly worked rectangular port heads, all new valvetrain, a fresh Weiand blower, etc. You need something like this! Here I am in utter amazement – yeah, that’s exactly what I need! Ron called the owner of it, helped broker the deal, and in 24 hours I paid for it in full – this time with the approval of the misses. Ron made me a fair offer to assemble it and drop it in the car and we shook hands on that as well.

The New Engine

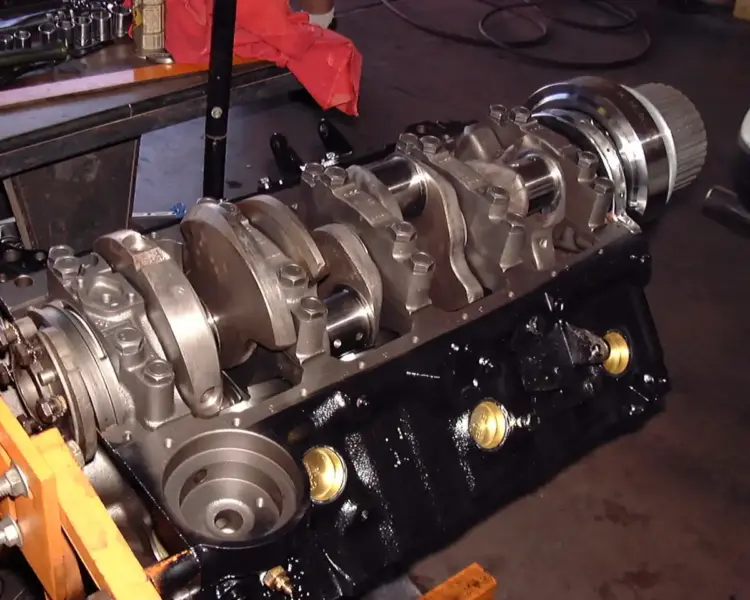

The new engine was a .030 over Gen IV 454 netting 461ci. It had a forged steel crank and rods, 8.5:1 TRW blower pistons, a pair of matched 3964291 rectangular port heads (early – 2.19 / 1.72 valves), a mild hydraulic flat tappet camshaft, Crane Gold rockers with Jomar stud girdles, and a freshly built Weiand 6-71 Blower – a nice, early 3 lobe with the Jimmy case and one piece front cover. It was perfect!

So, I licked my wounds and carted off all my old broke-ass shit. But, as it turned out, most of this junk was valuable – the block happened to be the 375hp version so that went to a local guy building an L78 375hp 396ci Nova. He was elated. The heads, well those were 3964291s – GM Hi-Perf heads that came on the LS6. I had them magnafluxed and they checked out fine, they just needed a complete overhaul. [The new motor had an identical set, just machined, and fully assembled if you can believe that.] They sold for good money on eBay. The blower kit also sold for great money on eBay – the buyer had rotor cores and gear sets and the case was fine. As it turned out, I raised more money selling this stuff than I spent on the new engine. Unbelievable, but true.

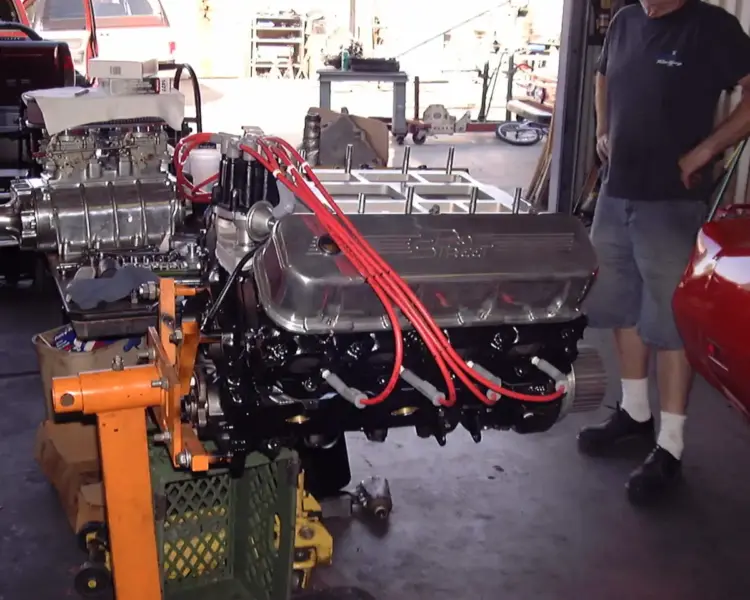

Ron and his son Junior had the engine assembled, in the car, and running in pretty short order. We had a few hiccups along the way, but nothing that couldn’t be overcome with money. The trans had two speeds, 1 and 3. It also had a corner broken off the case when I got it. Obviously, some bloke forgot to remove that bolt before attempting an engine removal. The axles were rolled and the differential was a “Lincoln Locker.” We took the opportunity to replace the guts with a Currie 9+ nodular center section, Moser spool and 35 spline axles, and a set of Yukon 4.30 gears – pulling the 4.86s which were in it. It also needed a full exhaust, which was handled by another shop in the same complex. 3″ all the way out the back, up and over the axle, with Flowmaster 40s – still in the car, it’s a work of art.

Success – It’s a Driver!

Once I got the car back, it’s been on the road ever since. The picture up at the top was taken within 6mos of getting the car back. That particular engine combination made good power (let’s call it 650) and got me out there cruising and enjoying it. I can’t thank Ron and Junior enough. Ron was first class throughout and was like a walking, talking encyclopedia of go-fast. When we met, Ron was determined to help me get out there and enjoy my car. Period. He is certainly among those who inspired me as I devised the formula for CE Auto Electric Supply. We lost Ron several years ago, may he Rest in Peace.

There’s a LOT More to the Story

Along the way, the Olds’ has been instrumental in helping to broaden my network. The electrical system disaster led to an opportunity to write a book on the topic, Automotive Wiring and Electrical Systems, which has now sold in excess of 60,000 copies! The book led to an opportunity to start an automotive electrical business which you know as CE Auto Electric Supply – which I began in 2011. In addition, the first book led to an opportunity to write a follow-up book, Automotive Electrical Performance Projects, in which I converted the engine in the Olds’ from carburetion to Electronic Fuel Injection. The 2nd book led to an opportunity to write the EFI Conversions Book. [Wow!]

The Olds’ has been a test bed for numerous product ideas and new product offerings. It has been instrumental in the product development for a wide variety of kits sold by CE Auto Electric Supply – our Battery Relocation Kits, Headlight Relay Kits, Vehicle Grounding Kits, Fan Relay Kits for example.

As the car gets all over the valley, more people know it than know me. It’s pretty universally liked so it just made sense for it to become part of our first t-shirt design. I wanted something that people wanted to wear. The Olds’ was a home run for this as I see folks wearing the shirts when I go to local events, which is awesome. The photo in the middle was the inspiration for the artwork. To say our Wearables and Swag have been well received would be an understatement!

In the next installment, I’ll cover how it got from where I left off to the end of the road for this particular combination. Go to Part 2!