Do I Really Need a Complete Battery Cable Kit?

This is an excellent question. If you own an older Diesel Truck, the battery cables are a source of many problems due to their age. After all, a solid charging system is the foundation for all other vehicle systems. As budgets tighten, you may ask yourself, “Can I just get by with replacing the parts which clearly require replacing?” We’ve all said it – you rarely save money when saving money, and this really applies here! Let me explain.

Cost Cutting & Value Engineering

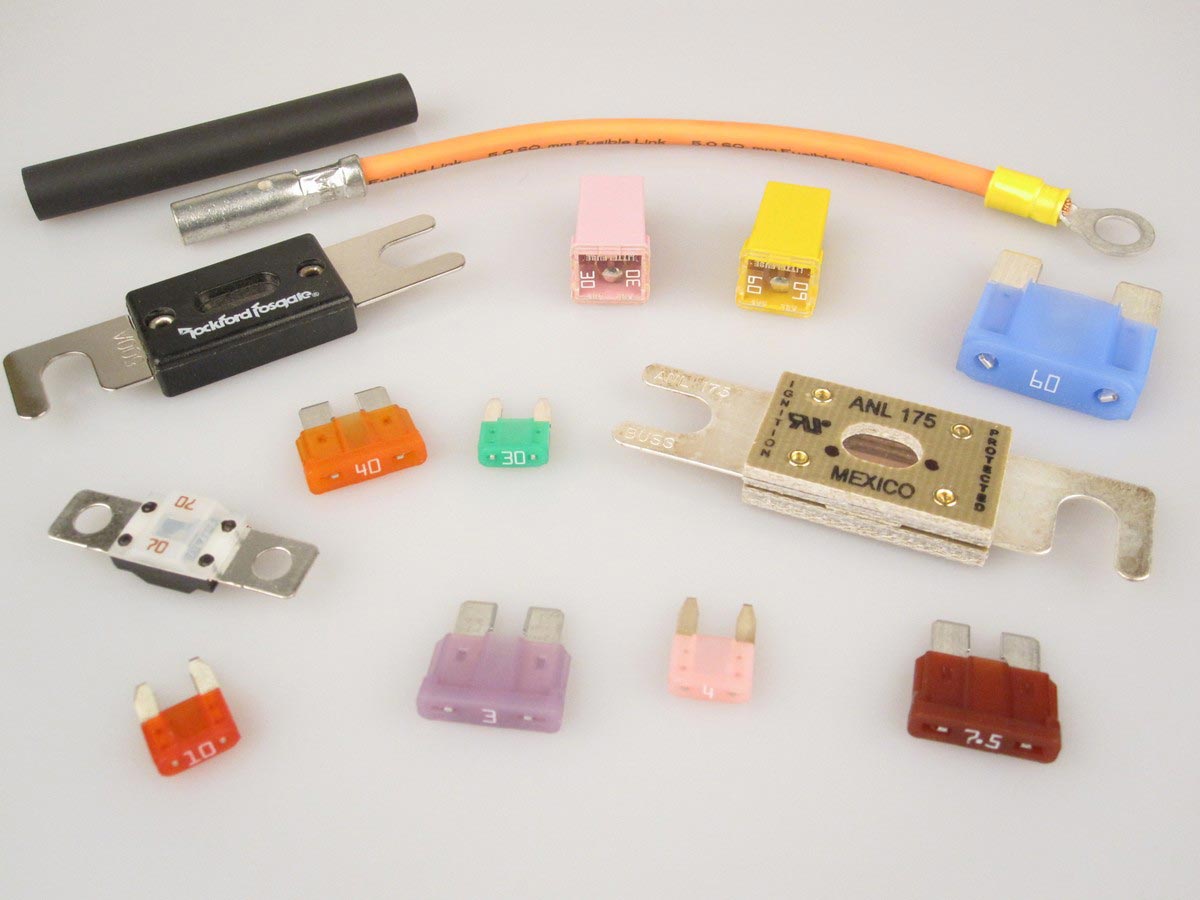

Rest assured that the cable kit for your truck was likely designed by engineers that desired the best performance. However, that costs money and corners simply have to be cut when mass producing vehicles. When bean counters get involved, they challenge the engineers – Do we really need 1/0 AWG Cable here? It costs 30% more than the next smaller size. Do we really need to heat shrink the cable ends – won’t the warranty be up by the time any benefit would be realized?

They also practice what is known as Value Engineering – cost cutting measures taken by the finance department as it applies to the parts listed on the Bill Of Materials set forth by the engineers that developed the cables to begin with. We found a similar part to this battery terminal spec’d in the BOM. It looks the same but it costs 40% less. Could we use it instead? So, compromises are made between engineering and finance to get something that’s workable but maybe less than ideal.

The CE Auto Electric Supply Difference – When I founded CE Auto Electric Supply, I had but one rule – No bean counters. Ever. Not as long as I steer the ship. As a result, our product development process is simple and elegant – we use the very best parts we can from a performance standpoint, regardless of cost. And we use the correct size cable for the application at hand – no exception. We make no apologies for the cost difference.

Performance Challenges as a Result of Age

The biggest challenges we see on stock cable sets which have been in service for some time are corrosion and oxidation of the conductors and terminations themselves which conspire to break down the cables. Copper cable corrodes and oxidizes over time. This is exacerbated by the elements (rain, moisture, dirt, mud) and further exacerbated by the absence of properly insulating and sealing the terminations with adhesive lined heat shrink during the assy process. Cables break down faster in areas known for their temperature extremes, areas which get snow, and especially those areas which combat snow via the use of salt on the roads.

Follow the ground cables from the battery negatives to the block, body, and frame. Follow the main cable to the starter. The ends of these cables are in the elements and terminated with eyelets. This is where the problems lie. These terminations break down from the inside out due to the aforementioned corrosion and oxidation which causes high resistance and poor performance. In many cases, you can’t even see it. Now, add the heat generated when flowing hundreds and hundreds of Amperes of current required by the starter through these high resistance terminations and they become a hazard!

At the batteries themselves, the battery terminals may be visibly worn or damaged. This is most often caused by repeated battery swaps, jump starts, and the addition of aftermarket electronics. Many are so excited to get their new accessory up and running that they’ll connect it any way they can – I’ll fix that later. Well, later is now. When the cable itself makes you think that should be replaced you’ve waited far too long!

The CE Auto Electric Supply Difference – We use only finely stranded tinned Oxygen Free Copper (OFC) Battery Cable of our own brand, made to our exacting specifications. Others may try and convince you that you don’t need that. More like because they don’t offer it . . . All terminations are via super thick tinned copper parts and insulated with adhesive lined heat shrink so that we keep the elements out. All terminations are performed with industrial grade electric over hydraulic crimping tools. [You can read more about the whys and hows of our parts selection and processes at our Custom Cables – The Story post.] Our goal is to make lifetime terminations once, have you install them once, and have your vehicle start better than it did new for the rest of the time you own it.

Fix vs Replace

So why not just repair the cables you already have and call it a day? To do that correctly, you’ll need to remove the cable set from the vehicle. You may have to then un-loom each of the cables to gain access to the terminations. Then, you’ll need to cut each of the cable ends off and . . . see a problem? Before you even get started, each of the cables will now be about 2″ shorter.

In some cases, the corrosion and oxidation is so bad that you’ll have to remove more than just the termination to resolve. As removing the factory cable set is the most difficult part of replacing them, you’re already half way there. Installing a complete CE Auto Electric Supply Battery Cable Kit puts you time and money ahead.

The CE Auto Electric Supply Difference

We’ve designed each Battery Cable Kit to be a perfect fit to the application. In addition, we’ve gone out of our way to design each in such a way that it resolves all of the shortcomings with the OEM design in the name of performance. No more slow cranking, drivability issues resulting from poor grounding, or premature battery failures. The performance difference between even a perfectly preserved OEM set is significant!

Consider the Battery Cable Kits we developed for the 2017-2019 Ford 6.7L Power Stroke Diesel Trucks. First, we get an OEM assembly from a vehicle in service, get it on the bench, open it up, and expose all it’s weaknesses!

After close examination and discussion with vehicle owners, we put our heads together and think – if we designed this from the word go, with cost as no object, how would we have done it? Well, here you go!

Notice the difference in quality across the board. The battery terminals and eyelets are not only a ton beefier (worthy to be under the hood of a Big Ol’ Super Duty Truck), they can also now be easily removed from the cable ends should they require replacement down the road – a $6.95 part and 5 minutes versus removing and replacing an entire cable assembly. Now, the R&R on this particular kit is laborious, which is a function of how it fits in the truck.

Owners report that the kits are simple to install, fit perfectly, and that the fit and finish exceeded their expectations. But, most importantly, they’re very happy with the performance as compared to the stock cable set! We’ve even provided take off studs on the battery terminals which facilitate the addition of aftermarket electronics.

Design Flaws

In addition to cost cutting and value engineering, some vehicles have serious design flaws with the battery cable sets that can cause battery failures, poor starting, and even cause damage to the vehicle if not corrected. Here are some things you should be aware of if you own one of the following vehicles.

2003-2009 Gen 3 Dodge Diesel Trucks

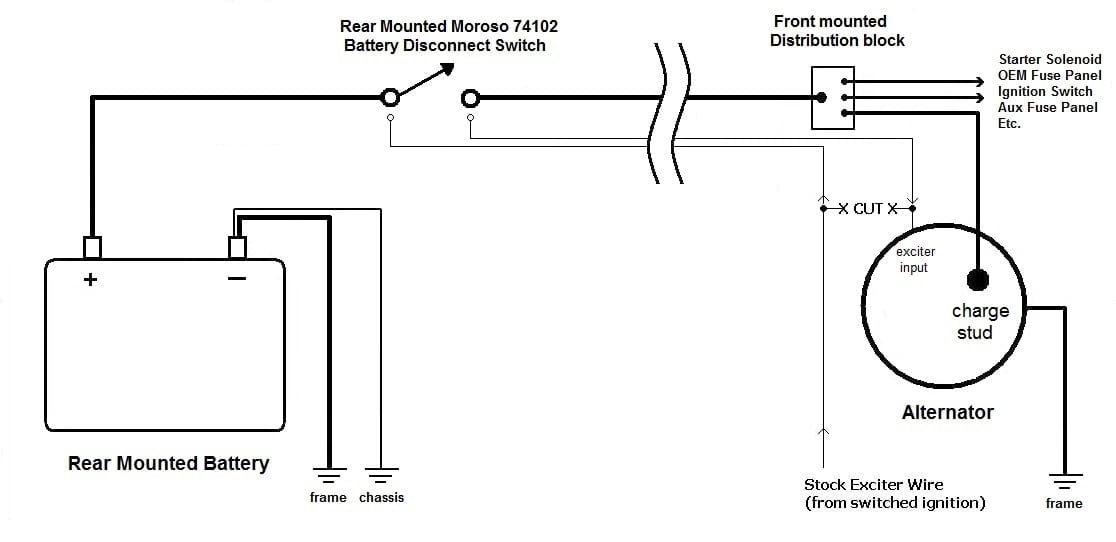

This affects all Gen 3 trucks with either the 5.9L or 6.7L Cummins diesel engines. The ECM manages the regulation of the alternator (how much voltage it outputs and when). To do so, it monitors the charge state of the batteries via a connection to the driver’s side battery. The charge lead from the alternator is connected to the passenger side battery.

As the cables breakdown as outlined above, the passenger side battery is overcharged – often to the point of it exploding. We have even seen cases where the ECU was damaged and unable to manage the regulation of the alternator. In some cases, an ECU swap restored this functionality, in other cases even that didn’t solve the problem – at which point, the alternator must be swapped to a more traditionally excited one.

2003-2007 Ford Super Duty Trucks and Excursions with the 6.0L Power Stroke Diesel Engine

Ford found it more cost effective to connect the main ground cable from the driver’s side battery to the frame and not to the engine block as it saved a few bucks on cable. This ground location is hardly ideal as it relates to the starter! As this location on the frame rusts and the cables break down over time, the driver’s side battery does very little when it comes to starting the engine.

So, the passenger side battery does all the heavy lifting when starting the engine. In addition, Ford used cheap, thin wall battery terminals which break down – I went to start my truck and I heard something pop, the battery terminal just blew in half!

2008-2010 Ford Super Duty Trucks with the 6.4L Power Stroke Diesel Engine

Exact same thing as the 6.0L vehicles!

2011-2019 Ford Super Duty Trucks with the 6.7L Power Stroke Diesel Engine

Thin wall battery terminals strike again! On these trucks, we often see the terminals in such bad shape that the plating is burned smooth off of them and they’re rusted! In addition, Ford intertwined the cables and part of the engine harness together making these trucks a real treat to repair. However, our kits are incredibly well thought out and the step-by-step instructions walk you through it.

In closing, I want you to know that we’re among the most passionate and dedicated as they come when it comes to designing and building Battery Cable Kits. I’ll stake my reputation on it! Please take a moment and view our complete selection of Battery Cable Kits to see if we offer one for your vehicle.

Tony Candela, owner